In order to better improve the quality of equipment and optimize the structure of equipment, the group integrates the mechanical design department and the production department, so that the design concept can be deeply understood by the production and processing personnel, and the problems existing in the production and processing can be fed back to the designers in time and corrected.

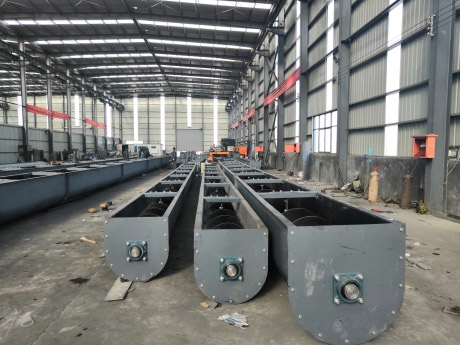

Advanced processing capabilities: The company's production and processing has advanced processing equipment, and is gradually transforming towards intelligence and digitalization.

The design of mechanical parts should realize 3D digitalization and parametric design, and conduct pressure test simulation in advanced professional software, actual simulation experiments of compression, torsion and tensile resistance to ensure the quality of equipment and the safety of the project.

The workshop has advanced mechanical processing equipment: CNC lathes, CNC drilling and milling machines, gantry planers, flaw detection rooms, digital 5-axis processing machines, digital laser cutting machines, CNC bending machines, CNC plate rolling machines and other sheet metal cutting equipment. In order to improve the corrosion resistance of equipment, the workshop has sandblasting and shot blasting rust removal equipment and dust-free spraying and baking paint workshops.

Reasonable mechanical structure design, advanced management concepts and mechanical processing equipment are the basis for ensuring product quality. Only by doing a good job of each equipment for the construction of the entire project can the entire project be perfectly delivered.