The crude palm oil (CPO) produced by the palm fruit bunch in the pressing plant contains a lot of impurities, mainly including cellulose, moisture, insoluble matter, free fatty acids(FFA), phospholipids, trace metals, oxidation products and odorous substances. Therefore, most crude palm oil must be refined before being eaten or used as an ingredient to make it more stable and non-irritating RBD oil.

Physical refining is mainly used for palm oil refining. The difference between the two is the different methods of removing FFA from palm oil.

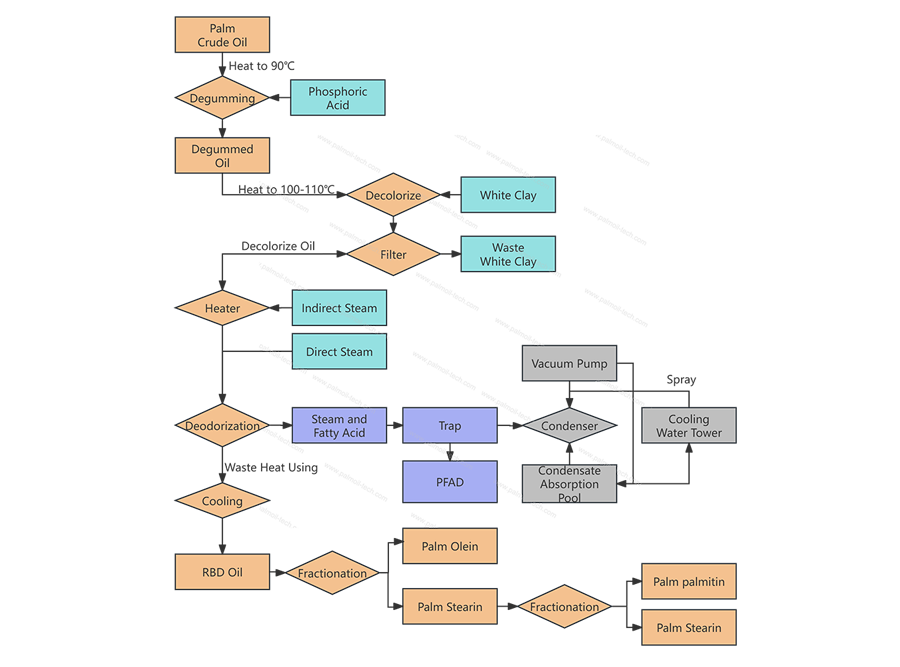

The main processes of physical refining are: degumming, decolorization and filtration, deacidification, and deodorization. Deacidification and deodorization are completed in a stainless steel pressure vessel.

Palm oil refining process flow and pollution-generating link diagram

(1) Pretreatment

Pretreatment refers to the process of adding concentrated phosphoric acid to palm oil to condense and precipitate non-hydratable phospholipids in the oil. In the refining of edible vegetable oils, vegetable oils with a high content of non-hydratable phospholipids are often accompanied by more metal ions. The presence of these metal ions will cause the vegetable oil to become corrupt and give the product an unpleasant taste. In order to obtain satisfactory flavor quality of vegetable oil, various phospholipid substances must be removed, i.e. degumming. For palm oil, it can directly enter the decolorization stage after a simple acid treatment, which is called dry degumming.

(2) Decolorization

Decolorization is an indispensable step in the refining process of vegetable oil. Generally, the crude oil processed contains pigment substances: natural pigments such as carotenoids and chlorophyll; pigments produced by oxidation, degradation and polymerization of sugars, vitamins and other substances during processing; pigments produced by metal derivatives of iron and copper.

After pretreatment, palm oil is added with bleaching clay for decolorization treatment, and the temperature is basically controlled at around 110°C. In the decolorization tower, the oil is depressurized and stirred to make the pigment and other substances fully contact with the adsorbent, so that the adsorbent is evenly distributed in the oil. The decolorization time is controlled at around 1 hour, and after complete adsorption, it enters the filter for filtration.

(3) Deodorization

Deodorization is the process of distilling free fatty acids, volatile odor substances and oxides in palm oil out of the deodorization tower under suitable temperature and steam stirring. Deodorization is a process of removing odor substances and volatile substances such as free fatty acids from oil under high temperature and high vacuum by means of the stripping effect of water vapor. The deodorization temperature is controlled at 240-250℃ by high-pressure steam, and the steam pressure is 50barg. After the oil is fully in contact with the steam, the gas stripped from each layer of the deodorization tower is discharged through the central exhaust pipe. The gas is partially condensed by the sprayed fatty acids at the top, and the uncondensed gas is extracted by the vacuum system. In the process of oil deodorization, many of the volatile components stripped are substances with high utilization value, such as free fatty acids and vitamin E. In order to recover these components, a fatty acid trap is connected to the exhaust channel coming out of the deodorization tower to capture them. When deodorizing oils with low free fatty acid content, the trap can be connected behind the first-stage jet pump, and when the free fatty acid content is high, it can be connected in front of the first-stage steam jet pump. The gas after passing through the fatty acid trap enters the vacuum system, which consists of a 2-stage condenser and a 4-stage steam jet pump. After the volatile gas is mixed with the steam, it is condensed by the condenser. After cooling the oil coming out of the deodorization tower, refined finished oil is obtained.

Table 5.2-1 Comparison table of raw materials, energy consumption, water consumption, etc. of the project with other processes

| Project | Value |

| POF yield of palm oil refining (%) | 99.0 |

| Fatty acid yield (t/t oil) | 0.0018 |

| Clay consumption (kg/t oil) | 10 |

| Steam consumption (t/t oil) | 0.17 |

| Fresh water consumption (t/t oil) | 0.25 |

| Electricity consumption (kWh/t oil) | 12 |

Palm oil fractionation project:

The carbon chain lengths of fatty acids in palm oil triglycerides vary, and the degree of unsaturation is also different, so that palm oil contains triglycerides with different melting points. By controlling the cooling crystallization process of palm oil and separating it, palm oil is separated into low melting point (palm olein) and high melting point solid (palm Stearin). The factors affecting the crystallization process of palm oil are mainly: oil composition, homogeneous crystals, and cooling conditions.

The purpose of palm oil fractionation: separate liquid oil (olein) and solid oil (stearin) by physical process to increase the value of the product.

Palm oil is a mixture of multi-component fatty acid glycerides with a melting point range of -30 to +70°C

Selectively cool and crystallize the triglyceride components with higher melting points to form crystals, thereby achieving separation. The selectivity of crystallization is achieved by temperature control during the cooling process.

The crystallization process consists of four parts: pre-cooling, nucleation, crystal growth, and final conditioning

Pre-cooling period: the oil is supercooled to the process temperature

Nucleation period: catalyzed by supercooling conditions and stirring conditions

Crystal growth period: proportional to supercooling conditions and inversely proportional to viscosity

Final conditioning: adjust the oil slurry mixture and prepare for filtration.

The main equipment for palm oil fractionation includes: crystallization tank, condensate system,Membrane press filter.

Palm oil refining is mainly divided into physical refining and chemical refining, the difference between the two is to remove the free fatty acids in palm oil in different ways.

The main process of physical refining: degumming, decolorization and filtration, deacidification and deodorization. Among them, deacidification and deodorization are done in stainless steel pressure vessel.

The main process of chemical refining: degumming, deacidification, decolorization and filtration, and deodorization. Among them, the soap produced by the deacidification process needs to be separated using a centrifuge.

The length of the fatty acid carbon chains in palm oil triglycerides varies, as well as the degree of unsaturation, so that palm oil contains triglycerides with different melting points. Palm oil is separated into low melting point (palm liquid oil) and high melting point solids (palm hard) by controlling the cooling and crystallization process and separation. The main factors affecting the palm oil crystallization process are: composition of the oil, homogeneous crystallization, and cooling conditions.