Palm kernel oil is a byproduct of palm oil pressing plant. The oil content of palm kernel after drying is about 48%. Palm kernel oil is rich in lauric acid C12 and myristic acid C14. It is the main source of high-end detergents and surfactants. The market demand for palm kernel oil is increasing year by year, and the supply is in short supply. It is widely used as an organic raw material for health foods, medicines, cosmetics, detergents and other products, and has a relatively high market value.

Overview of palm kernel oil pressing process: Palm kernels collected from palm oil pressing plants are dried and pressed twice to obtain crude palm kernel oil (CPKO) and palm meal (PKM). Palm kernel meal is crushed, fermented and packaged as animal feed ingredients.

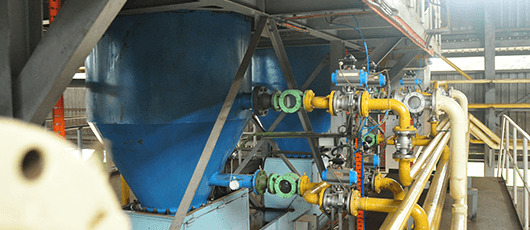

After the pressing, the oil residue of the palm kernel oil is filtered and recovered after sedimentation and re-pressed. The palm kernel oil is filtered and dried and stored. The main equipment includes: kernel drying bin (optional), palm kernel spiral & scraper conveyor, slag remover, disc filter, air compressor, palm kernel oil storage tank.

The secondary pressing process is widely used in the market, but the palm meal after the secondary pressing still contains about 8-10% oil. If it is not considered as animal feed, the single pressing + leaching process can be used, which can greatly increase the output, and the residual oil in the meal can be controlled to ≤1%. Customers can choose different processes according to their needs.

Palm kernel is conveyed to palm kernel temporary storage bin through screw conveyor, the lower outlet adopts plug-type gate, which can control the feeding speed.Palm kernel enters the palm kernel press, the oil in the palm kernel is extruded by physical screw extrusion, the oil flows out through the filter slit, and the palm meal is discharged in the conical pressure unit at the end.

The temperature of the press chamber needs to be controlled at about 85°C during the pressing process. The amount of palm meal after pressing is 20-24%.

the second pressing and the first pressing with the difference of the press, pressure and speed need to be adjusted, the second pressing of the palm meal containing 8-10% oil.

The extraction section is an optional step for businessmen, the palm meal after primary or secondary crushing is extracted by leachers using 6# solvent oil n-hexane (C6H14), and continuous desolvation of the palm meal, and solvent recycling and utilization.

the gross oil after pressing is collected in a grease with partition, adopting the principle of different density of oil and water, the residue will be collected in 1# partition kind, after 2# partition to separate again, the clarified gross oil will be collected in 3# partition.

The palm kernel oil produced by pressing or leaching contains oil solid impurities and tiny meal particles, which are filtered through the vane filter to separate the oil from the solids. The vane filter adopts pneumatic automatic discharge filter, and the screen is cleaned automatically.

Adopting two methods of intermittent sedimentation drying and continuous vacuum drying to remove the remaining water in the oil. Customers can choose the configuration according to the output size. It is recommended to adopt vacuum drying mode for large output.