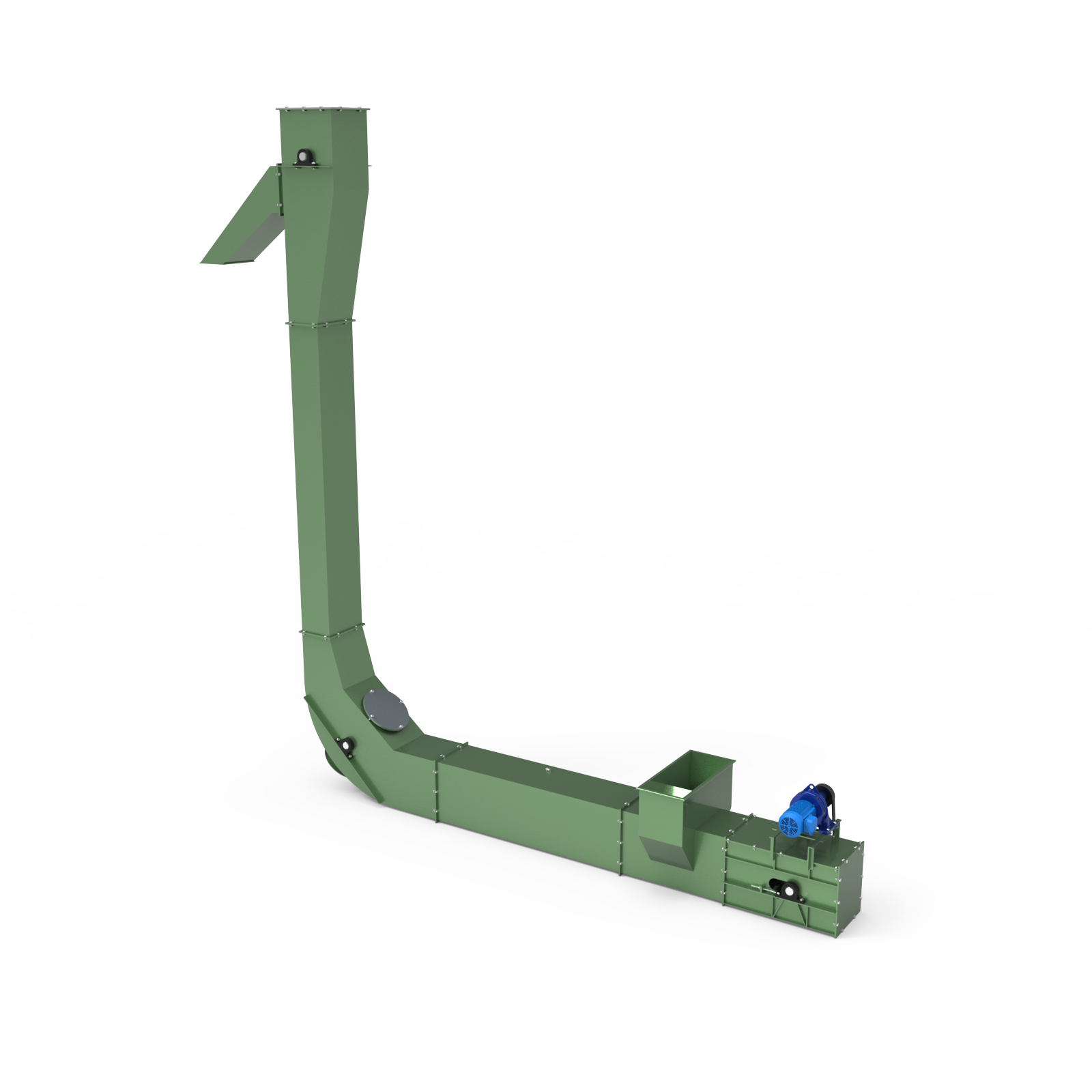

An enhanced conveying solution for oil extraction processes, featuring integrated drainage screen plates and compression sections to pre-desolventize wet meal. This reduces steam consumption in desolventizer-toasters (DTDC), lowers residual oil/solvent in meal, and increases overall production capacity.

An enhanced conveying solution for oil extraction processes, featuring integrated drainage screen plates and compression sections to pre-desolventize wet meal. This reduces steam consumption in desolventizer-toasters (DTDC), lowers residual oil/solvent in meal, and increases overall production capacity.

Energy Efficiency:

Pre-removes 15-20% solvent from wet meal

Cuts DTDC steam consumption by 25-30%

Compact Design:

Space-saving structure with multi-point loading/unloading

30% lighter than conventional conveyors

Bidirectional Operation:

Simultaneous material transport in opposite directions

Explosion-Proof Safety:

Low-speed operation (≤0.2 m/s) minimizes ignition risks

IP65-rated enclosure for hazardous environments

Wet meal enters enclosed trough

Drag chains move material through:

Drainage screens: Gravity-based solvent removal

Compression zone: Mechanical dewatering

Pre-dried meal discharges to DTDC

Recovered solvent returns to extraction cycle

Oilseed Processing: Transporting solvent-laden wet meal (soybean, rapeseed)

Hazardous Material Handling: Dusty, toxic, or explosive powders

Environmental Protection: Fully enclosed design prevents VOC emissions

| Parameter | Range |

|---|---|

| Capacity | 5-200 TPH |

| Trough Width | 300-1000 mm |

| Chain Speed | 0.05-0.2 m/s |

| Power | 3-30 kW |

| Material | SS304/316L carbon steel |

Daily: Inspect chain tension and screen cleanliness

Weekly: Lubricate bearings; check wear liners

Monthly: Calibrate explosion relief valves

Annually: Replace chain/sprocket assemblies

The Enclosed Drag Chain Conveyor delivers 15% operational cost savings through integrated solvent recovery and failsafe hazardous material handling. Engineered for maximum reliability in oil extraction plants, it supports sustainable production while meeting ATEX Zone 21 safety standards.