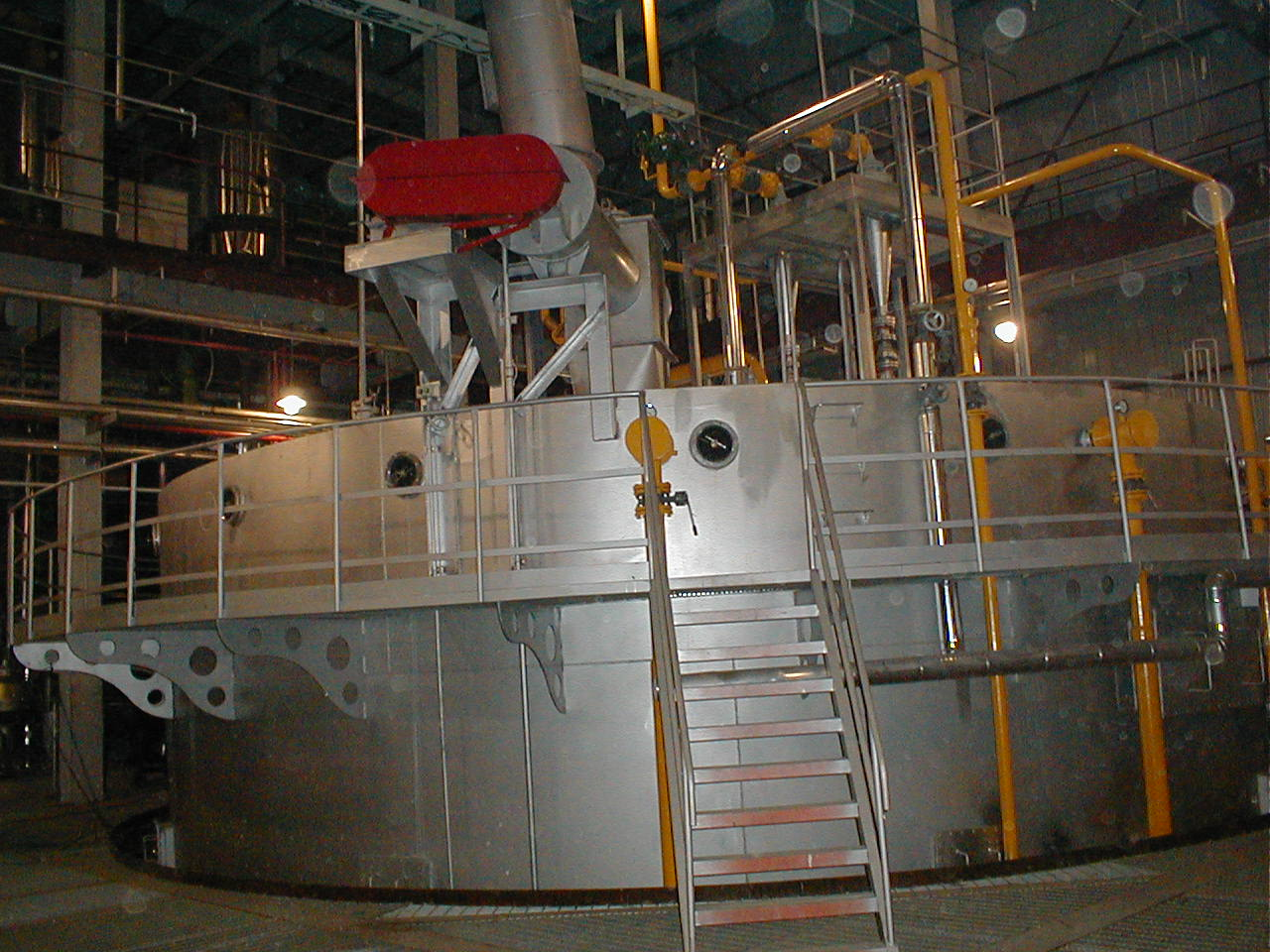

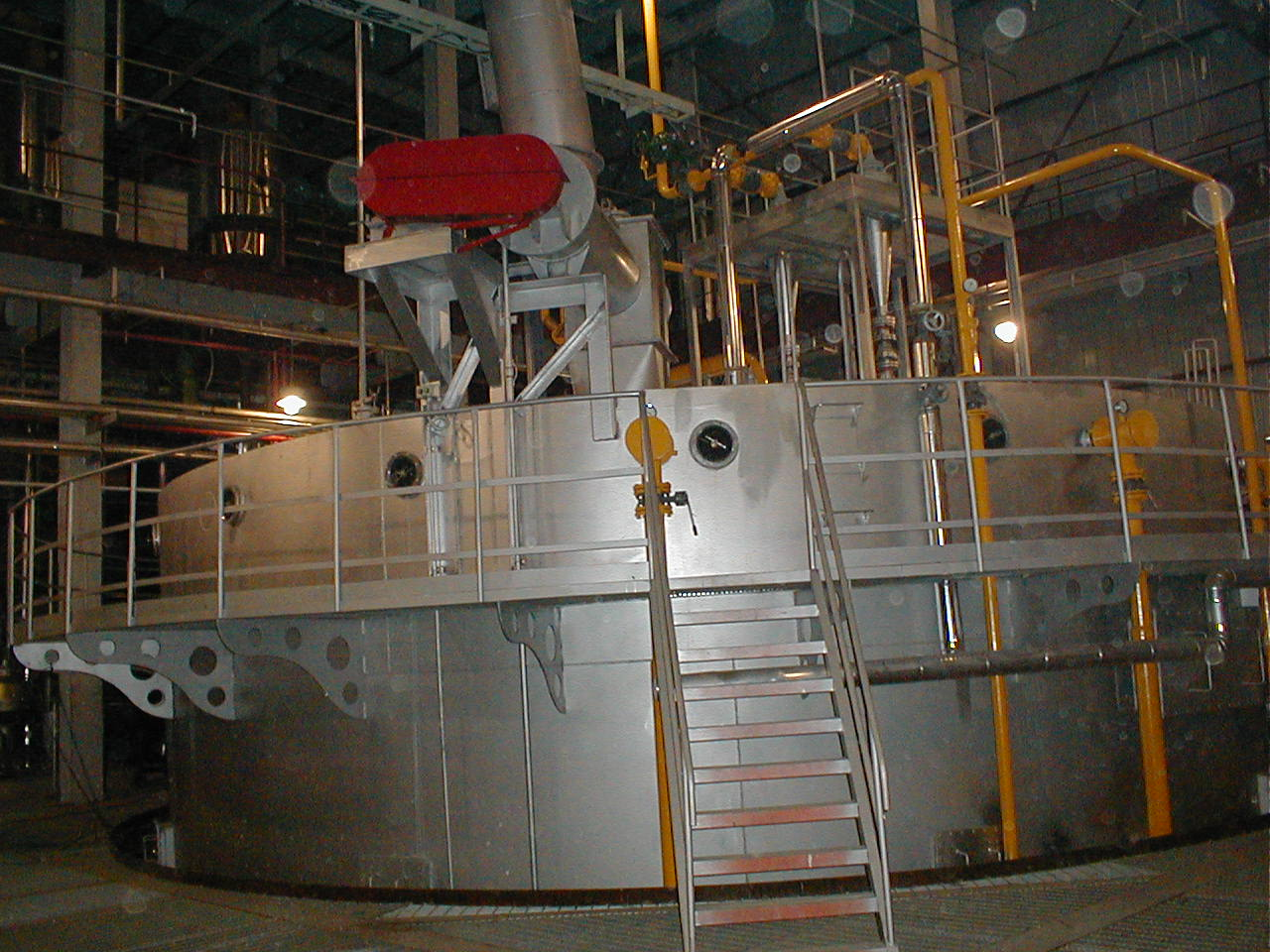

The Vertical Leacher is equipment used in the oil processing industry to extract oil from oilseeds. It utilizes a vertical leaching vessel where oilseeds contact solvents (e.g., hexane). The solvent dissolves the oil, forming miscella. The miscella undergoes evaporation and stripping to separate the solvent, yielding pure oil

The Vertical Leacher is equipment used in the oil processing industry to extract oil from oilseeds. It utilizes a vertical leaching vessel where oilseeds contact solvents (e.g., hexane). The solvent dissolves the oil, forming miscella. The miscella undergoes evaporation and stripping to separate the solvent, yielding pure oil. Its vertical design enables periodic batch processing in single vessels, facilitating production coordination and suiting intermittent operations.

Vertical Structure: Space-efficient design enhances productivity.

High-Pressure Operation: Improves leaching efficiency in specific applications.

Mechanical Agitation-Free: First-generation models eliminate complex stirring mechanisms, reducing maintenance.

Multi-Stage Series Operation: Enhances extraction efficiency through cascading vessels.

Efficient Solvent Recovery: Integrated systems separate and recycle solvents from miscella.

Oil Processing: Extracts oil from palm kernel meal, soybeans, rapeseed, peanuts, etc.

Metallurgy: Used in high-pressure acid leaching (HPAL) of laterite nickel ore to extract nickel and cobalt.

Sugar Industry: Extracts sucrose from sugar beet cells.

Capacity: Match processing capability to production scale.

Solvent Consumption: Prioritize low-solvent models to reduce costs.

Steam Consumption: Select energy-efficient designs.

Material: Opt for corrosion-resistant materials (e.g., titanium-clad steel) for longevity.

High Efficiency: Vertical design and pressure operation optimize extraction.

Energy Savings: Efficient solvent recovery and low steam consumption lower operating costs.

Operational Stability: Agitation-free design minimizes complexity and maintenance.

Safety & Reliability: Stable operation reduces safety risks.

Vertical Leachers are efficient, energy-saving, and safe, making them essential in oil processing and ore leaching industries.